Product / System Data Sheets

All files are in PDF format. Click the category tabs below to access the TDS/SDS for specific products.

CRACK/JOINT FILLER

Filling your cracks and joints is an essential step to achieve professional results. Use our fast-set joint filler to create a seamless flooring system.

| Product Name | Benefits/Features | Mix-Ratio | Coverage | Cure Schedule |

|---|---|---|---|---|

| SPE-JS - Fast Set Flexible Joint Sealant Clean joint, prepare tube via instructions, place backer rod in joint, use dual cartridge gun to apply. TDS SDS |

• Achieve a seamless floor • Fast settting • Flexible • Packaged in tube sets for use with a dual cartridge gun • Available in larger kits for use in plural component pump equipment Application Temp: 60-90°F with relative humidity below 85% |

1:1 | Approximate for 1 tube set @ 1⁄2” wide by 1⁄2” deep: 11 to 12 feet |

Based on 70°F Working Time 1 to 2 mins Recoat/Topcoat 1 hr Lt. Foot Traffic 1 to 3 hrs |

| CF100 - 100% Epoxy Crack Repair / Filler Apply with a marginal trowel, putty knife, or any other suitable equipment. TDS SDS |

• Can topcoat immediately after application • Applied by trowel, putty knife, or other suitable equipment • Vertical/horizontal applications Application Temp: 60-90°F with relative humidity below 85% |

1:1 | 1,228 lineal feet @ 1/8” x 1/8” per gallon |

Based on 70°F Working Time 1 to 3 hrs Recoat/Topcoat Immediately after application Lt. Foot Traffic 10 to 24 hrs |

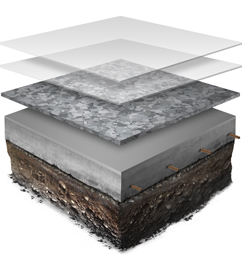

PRIMERS

Primers can improve the adhesion of your resinous flooring system, improve durability, and extend the life of your investment.

| Product Name | Benefits/Features | Mix-Ratio | Coverage | Cure Schedule |

|---|---|---|---|---|

| HDWB - Waterborne Epoxy Primer Dip and roll with a 3/8” nap roller TDS SDS |

• Low odor, no strong solvents • Good chemical resistance • Excellent abrasion resistance • Excellent substrate penetration • Clear and Pigmented Application Temp: 55-90°F with a relative humidity below 75% |

4:1 | 200 to 310 ft² gallon at 5-7 mils thickness | Based on 70°F Working Time 1 to 1.5 hrs Recoat/Topcoat 7 to 10 hrs Lt. Foot Traffic 16 to 24 hrs |

| HDWB Fast Set - Waterborne Epoxy Primer Dip and roll with a 3/8” nap roller TDS SDS |

• Low odor, no strong solvents • Good chemical resistance • Excellent abrasion resistance • Excellent substrate penetration Application Temp: 55-90°F with a relative humidity below 75% |

4:1 | 200 to 310 ft² gallon at 5-7 mils thickness | Based on 70°F Working Time 1 to 1.5 hrs Recoat/Topcoat 4 to 6 hrs Lt. Foot Traffic 12 to 16 hrs |

| HDPRO - High Solids Epoxy Pour, flat or 3/16" notched squeegee to spread, back roll with 1/4” nap roller TDS SDS |

• Can be used as a Mid Coat

• Great chemical resistance • Ideal for applications that require a lower mil high solids epoxy • Used as a stand-alone product • Pigmented Only • Low VOC • Could contribute to LEED points Application Temp: 55-90°F with a relative humidity below 75% |

2:1 | 133 to 267 ft² gallon at 6-12 mils thickness | Based on 70°F Working Time 30 to 45 mins Recoat/Topcoat 10 to 14 hrs Lt. Foot Traffic 12 to 16 hrs |

| FLEX - Flexible Broadcast Epoxy Pour, flat or notched squeegee to spread, then backroll TDS SDS |

• Extremely flexible product • Great for sealing severely cracked or spider-webbed concrete • Use over wood subfloor • Low VOC • Could contribute to LEED points • Clear (tinting available) Application Temp: 55-90°F with a relative humidity below 75% |

1:1 | 32 to 160 ft² gallon at 10-50 mils thickness | Based on 70°F Working Time 15 to 25 mins Recoat/Topcoat 8 to 12 hrs Lt. Foot Traffic 12 to 24 hrs |

| Vapor Pro See TDS sheet for detailed instructions. TDS SDS |

• Reduce effects of moisture vapor • Available in clear only • Easy to apply • Use as a primer over any system • VOC Compliant / Low Odor • 100% Solids Application Temp: 60-90°F with a relative humidity below 90% |

2:1 | 95 ft² gallon at 17mils thickness | Based on 70°F Working Time 28 to 38 mins Recoat/Topcoat 12 to 16 hrs Lt. Foot Traffic 16 to 18 hrs |

| Oil Stop Primer Dip and Roll with a 3/8” Nap Roller TDS SDS |

• Primer for oil contaminated concrete surfaces • Available in black only • Good chemical resistance Application Temp: 55-90°F with a relative humidity below 75% |

1:1 | 200 to 320 ft² gallon at 5-8 mils thickness | Based on 70°F Working Time 2 to 4 hrs Recoat/Topcoat 4 to 8 hrs Lt. Foot Traffic 16 to 24 hrs |

Mid Coats / Body Coats

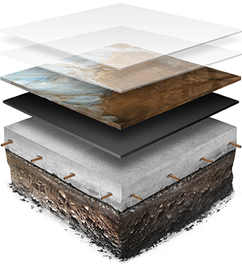

Mid and Body Coats are essential for a high-build resinous flooring solution. These industrial-grade products provide a mid to high mil thickness. Applying these types of systems to your floor can hide concrete imperfections. We have a variety of products that are available both clear and pigmented.

| Product Name | Benefits/Features | Mix-Ratio | Coverage | Cure Schedule |

|---|---|---|---|---|

|

CLEAR100 - 100% Clear Epoxy Pour, flat squeegee, then back roll with 1/4” nap roller. TDS SDS |

• Used in our Metallic Epoxy system • Use as body and top coat in flake and quartz • Good chemical resistance • Good UV stability • Clear only Application Temp: 60-90°F with a relative humidity below 85% |

2:1 | 50 to 100ft² gallon at 16-30 mils thickness | Based on 70°F Working Time 30 to 35 mins Recoat/Topcoat 10 to 16 hrs Lt. Foot Traffic 14 to 18 hrs |

| CLEAR100 UV - UV Binder / Top Coat Pour, flat squeegee, then backroll with 1/4” nap roller. TDS SDS |

• Use as body and top coat in flake, quartz, and metallic systems • Good chemical resistance • Good UV stability • Clear only Application Temp: 60-90°F with a relative humidity below 75% |

2:1 | 80 to 100ft² gallon at 16-18 mils thickness | Based on 70°F Working Time 30 to 35 mins Recoat/Topcoat 10 to 14 hrs Lt. Foot Traffic 14 to 18 hrs |

| ACCEL100 - High Build Fast-Set 100% Epoxy Pour, flat or notched squeegee to spread, then backroll TDS SDS Ask Us |

• Good chemical resistance • Use when high build, colorfast, impact resistant floor is needed • Ideal for colder temperature installs (45°F) • Use when fast-set high build is needed • HPU, TC92, and other topcoats compatible. Application Temp: 45-90°F with a relative humidity below 85% |

2:1 | 53 to 130ft² gallon at 12-30 mils thickness | Based on 70°F Working Time 30 to 45 mins Recoat/Topcoat 8 to 12 hrs Lt. Foot Traffic 12 to 24 hrs |

| PRO100 - High Build Epoxy Pour, flat or notched squeegee to spread, then backroll TDS SDS |

• Good chemical resistance • Use when high build, colorfast, impact resistant floor is desired • Pigmented only • Core Product Application Temp: 60-90°F with a relative humidity below 85% |

2:1 | 53 to 130ft² gallon at 12-30 mils thickness | Based on 70°F Working Time 30 to 45 mins Recoat/Topcoat 8 to 12 hrs Lt. Foot Traffic 12 to 24 hrs |

EPOXY MORTARS AND SLURRIES

High-impact, heavy-duty, resurfacers, and patching products that are extremely durable, shock and chemical resistant for every application need. You can use a variety of our epoxies and urethanes to add even more protection including applying a novolac topcoat to our WBSL system which creates an acid-resistant flooring system. Ask any of our Spartan Epoxies Experts for more information.

| Product Name | Benefits/Features | Mix-Ratio | Coverage | Cure Schedule |

|---|---|---|---|---|

|

Epoxy Mortar Mix Part A and B liquids thoroughly in an oversized bucket, then add aggregate. Mix all parts equally until streak-free. Apply the mixed material at 1/8 to 1/4 inch thickness. Apply the material with a hand trowel or other suitable application equipment. Spec Sheet |

• Heavy Traffic Areas • Fork Lift Traffic • Steel Wheel Equipment Safe • 3 Part 100% solids epoxy mortar - which displays ultra high wear characteristics and strength • Available in larger kits for use in plural component pump equipment Application Temp: 55-90°F with relative humidity below 85% |

1:1 | 21.54 sq. ft. @ 1/4" and 43.1 sq. ft. @ 1/8" | Based on 70°F Working Time 30-40 mins Recoat/Topcoat 7-8 hours Lt. Foot Traffic 14-16 hrs Full Cure 2-7 Days |

| WBSL - Slurry Apply with a Cam Rake @ 1/8" to achieve a 3/16" finished floor. Backroll in a perpendicular direction with a spiked roller to settle aggregate and remove cam rake lines. Broadcast desired aggregate or flakes until rejection. TDS Spec Sheet |

• Bio-based 4-3 Part high wear - high heat system • Resistant to MVT • Seamless hygienic finish with no grout lines • Thermal shock and chemical resistance • Top coat with a Novolac or other urethane • Withstands frequent hot water wash downs Application Temp: 45-85°F with relative humidity below 85% |

See TDS | 37 to 46 square feet per kit at approximately 1/8” | Based on 75°F Working Time 15-20 mins Heavy Foot Traffic 24 hours Lt. Foot Traffic 12 Hours Full Cure 7 Days |

|

TEC100 Coal Tar Epoxy Coating Mix equal volumes of the two components with a jiffy mixer or other suitable equipment until thoroughly mixed. Do not leave mixed material in the bucket. Pour out along the back wall, then spread with a 12 mil notched squeegee at a rate of 130 to 140 sq ft. per gallon, then back roll with a 3/16" nap roller cover. TDS |

• Resurfacing asphalt base substrates • 100% Solids and 0 VOC • Treat surfaces contaminated by petroleum • Superior adhesion and resilience Application Temp: 55-90°F with relative humidity below 85% |

1:1 | 130 to 140 sq ft. per gallon | Based on 55-90°F Working Time 20-30 mins Recoat/Topcoat 7-9 hours Lt. Foot Traffic 14-16 hrs Full Cure 2-7 Days |

Urethane Topcoats

Urethane top coats offer a protective coating over your resinous flooring system. Each urethane top coat that we offer has a variety of characteristics. From adding more chemical resistance, color stability, scratch, and abrasion resistance, as well as providing unique finish options. They can also be used to achieve a specific gloss finish such as low, satin and high gloss. Talk to a Spartan sales consultant today to learn more.

| Product Name | Benefits/Features | Mix-Ratio | Coverage | Cure Schedule |

|---|---|---|---|---|

| SPE-HDI - One Component Moisture Cured

Dip and roll with a 3/8” nap roller TDS SDS |

• One component product • Superior characteristics for abrasion resistance, chemical resistance and UV stability • High Gloss Finish • Add HWS additive for anti-slip Application Temp: 50-90°F with a relative humidity below 60 - 90% |

1 Part | 400 to 800 ft² gallon at 2-5 mils thickness | Based on 70°F Working Time 1 to 1.5 hrs Recoat/Topcoat 9 to 13 hrs Lt. Foot Traffic 13 to 24 hrs |

| HPU - High Performance Urethane Dip and roll with a 3/8” nap roller TDS SDS |

Excellent chemical resistance • Excellent abrasion resistance • Excellent flexibility / UV stability • High Gloss or Semi-Gloss Finish • Clear and Pigmented • Add HWS additive for anti-slip Application Temp: 45-90°F with a relative humidity below 50 - 90% |

2:1 | 320 to 500ft² gallon at 3-5 mils thickness | Based on 70°F Working Time 1 to 2 hrs Recoat/Topcoat 5 to 9 hrs Lt. Foot Traffic 14 to 18 hrs |

| WBG - Waterborne Urethane Dip and roll with a 3/8” nap roller TDS SDS |

High Gloss or Low Gloss Finish • Low Odor • Excellent chemical resistance • Excellent abrasion resistance • Excellent UV resistance Application Temp: 60-90°F with a relative humidity below 85% |

2:1 | 320 to 500ft² gallon at 3-5 mils thickness | Based on 70°F Working Time 2 to 4 hrs Recoat/Topcoat 8 to 12 hrs Lt. Foot Traffic 24 hrs |

| TC92 - High Wear Urethane Dip and roll with a 3/8” nap roller TDS SDS |

Excellent chemical resistance • Excellent abrasion resistance • Excellent flexibility • Excellent UV stability • Low VOC • Clear or Pigmented • Semi-Gloss / Eggshell Finish • 3 Component Product Application Temp: 50-90°F with a relative humidity below 50 - 90% |

1.8# Part A with 6.45# Part B and 3.0# Part C | 600ft² gallon at 2-3 mils / 660ft² gallon if pigmented | Based on 70°F Working Time 1 to 2 hrs Recoat/Topcoat 6 to 10 hrs Lt. Foot Traffic 14 to 24 hrs |

Polyaspartic Urethanes

Spartan Epoxies offers a comprehensive range of Polyaspartic Urethane products designed to meet diverse application requirements with utmost precision and quality. Our Polyaspartic Urethanes stand out in the market due to their exceptional performance and numerous benefits.

| Product Name | Benefits/Features | Mix-Ratio | Coverage | Cure Schedule |

|---|---|---|---|---|

| HP44 Polyaspartic Sealer / Binder Pour, squeegee, then back roll with 3/16" Nap Roller. TDS SDS Ask US |

Polyaspartic / High Gloss Finish • User Friendly Working Time • Low VOC and California Compliant • 1 coat over Full Flake @ 100FT² Per Gallon • Great for Metallic Epoxy • Excellent in industrial applications • Excellent hardness • Excellent clear gardner color • Excellent chemical resistance • Excellent abrasion resistance • Excellent UV resistance Application Temp: 50-90°F with a relative humidity below 85% |

1:1 | 1 Coat @ 100ft² over Full Flake or 130 to 200ft² per gallon. |

Based on 70°F Working Time 10 - 20 mins Recoat/Topcoat 6 to 9 hrs Lt. Foot Traffic 3 to 5 hrs Full Cure 2 - 7 Days |

| PC66 Polyaspartic Coating Pour, squeegee, then back roll with 3/16" Nap Roller. TDS SDS ask us |

Polyaspartic / High Gloss Finish • Quick to Light Foot Traffic (1-2 hrs) • Recommended for broadcasted systems • Excellent in industrial applications • Excellent hardness • Excellent clear gardner color of 1 • Excellent chemical resistance • Excellent abrasion resistance • Excellent UV resistance Application Temp: 50-90°F with a relative humidity below 85% |

1:1 | One Coat System: 90 to 100 ft² gallon at 16-18 mils thickness Two Coat System: Coat 1: 135 to 160 ft² gallon Coat 2: 150 to 200 ft² gallon |

Based on 70°F Working Time 30 mins Recoat/Topcoat 2 to 3 hrs Lt. Foot Traffic 1 - 2 hours Full Cure 24 - 48 hrs |

| XC75 Coating

Dip and Roll using roller to spread, then back roll with 3/8" nap. OR Pour, squeegee, then back roll with 3/16" Nap Roller. See TDS for complete info. TDS SDS ask us |

Polyaspartic / High Gloss Finish • Cost Effective • Quick Tack Free Time (1-2 hrs) • Recommended for broadcasted systems • Excellent in industrial applications • Pigment with our Universal Pigments • Clear Gardner color • Excellent UV & chemical resistance • Outstanding abrasion resistance • Long working time if dip and roll Application Temp: 48-90°F with a relative humidity below 85% |

1:1 | One Coat System: 100 ft²/gallon at 16-18 mils thickness Two Coat System: Coat 1: 100 ft²/gallon Coat 2: 100 to 150 ft²/gallon |

Based on 70°F Working Time 30 mins Recoat/Topcoat 1 to 10 hrs Lt. Foot Traffic 4 - 6 hours Full Cure 5 - 7 hrs |

| PC85 Polyaspartic Sealer / Binder Pour, squeegee, then back roll if needed. TDS SDS |

Polyaspartic / High Gloss Finish • Fast set - 3 - 5 hrs Lt Foot Traffic • High Gloss Finish • Min Tack Free Time • Excellent Hardness • Excellent clear gardner color • Excellent chemical - abrasion resistance • Recommended over Full Broadcast • Excellent UV resistance Application Temp: 50-90°F with a relative humidity below 50 - 85% |

2:1 | 200ft² - 800ft² gallon at 8 - 2 mils |

Based on 70°F Working Time Less than 15 mins Recoat/Topcoat 2 to 4 hrs Lt. Foot Traffic 3 to 5 hrs Full Cure 24 to 48 hrs |

| PS95 Polyaspartic Sealer / Binder Pour, squeegee, then back roll if needed. TDS SDS ASK US |

Polyaspartic / High Gloss Finish • Fast set - 3 - 5 hrs Lt Foot Traffic • Use as a binder for metallic epoxy • Excellent hardness • Excellent clear gardner color • Excellent chemical resistance • Excellent abrasion resistance • Excellent UV resistance Application Temp: 50-90°F with a relative humidity below 50 - 90% |

12.95lbs Part A to 9.3lbs Part B | 80ft² to 100ft² gallon at 16 - 8 mils | Based on 70°F Working Time Less than 28 mins Recoat/Topcoat 3 to 5 hrs Lt. Foot Traffic 3 to 5 hrs Full Cure 24 to 48 hrs |

| PS100 Seamless Binder Variety of application techniques. Ask your Spartan Expert. TDS SDS ASK US |

Polyaspartic / High Gloss Finish • Fast set - 1 - 2 hrs Lt Foot Traffic • Excellent clear gardner color • Excellent clear gardner color • Excellent chemical resistance • Excellent abrasion resistance • Excellent UV resistance Application Temp: 50-90°F with a relative humidity below 85% |

1:1 | 25 to 80ft² gallon | Based on 70°F Working Time Less than 10 mins Recoat/Topcoat 2 to 3 hrs Lt. Foot Traffic 1 - 4 hrs Full Cure 24 - 48 hrs |

SEALERS

Coming Soon, If you are in need of a system specification sheet, SDS, or TDS please start a chat, email us at spartanepoxies@gmail.com and let us know and a Spartan Experts will take care of your requests.

XRC PRO - SYSTEM GUIDES / SPEC SHEETS

The XRC PRO system is a high-performance, single-component polyurethane coating designed for a wide range of exterior applications. This elastomeric coating system, also known as a traffic deck coating, is particularly recommended for areas requiring durable and flexible waterproofing solutions. It's ideal for use in environments such as parking garages, balconies, and outdoor concert venues. The system stands out for its ability to bridge substrate cracks and maintain flexibility in varying temperatures, ensuring long-term integrity and resilience. With its excellent resistance to UV rays, abrasion, and chemicals, the XRC PRO system is suitable for both pedestrian and vehicular traffic areas, making it a versatile choice for projects demanding robust protective coatings.

ANTISLIP - SKIDPROOFING COATINGS AND ADDITIVES

Coming Soon, If you are in need of a system specification sheet, SDS, or TDS please start a chat, email us at spartanepoxies@gmail.com and let us know and a Spartan Experts will take care of your requests.

ESD/ANTI-STATIC COATINGS

Coming Soon, If you are in need of a system specification sheet, SDS, or TDS please start a chat, email us at spartanepoxies@gmail.com and let us know and a Spartan Experts will take care of your requests.

AGGREGATES / FLAKES

Coming Soon, If you are in need of a system specification sheet, SDS, or TDS please start a chat, email us at spartanepoxies@gmail.com and let us know and a Spartan Experts will take care of your requests.

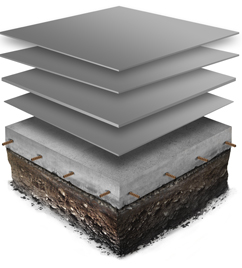

SYSTEM SPECIFICATION SHEETS

Are you interested in specifying a Spartan Epoxies system for your upcoming project, or are you a contractor bidding on a job that requires the use of a Spartan Epoxies system? Perhaps you're simply in search of the best system offered by Spartan Epoxies. You've come to the right place to begin your exploration! We have a wide range of systems available, and if you don't find one that perfectly fits your application requirements, our team is ready to assist you in creating a customized system tailored specifically for your needs. Feel free to reach out and speak with a Spartan Epoxies Expert today.